Not all recycled vegan leathers are created equal. This guide compares Fruit Leather, RPVB Leather, and Solvent-Free Vegan Leather in terms of recyclability, cost, performance and market fit.

Choosing a sustainable leather option isn’t just about going vegan. It’s also about how much can be recycled.

Fruit leather, RPVB leather, and solvent-free vegan leather all offer eco alternatives—but their costs, recyclability, and stability vary widely.

Not all recycled vegan leathers1 are created equal. Some reach near 100% recyclability which fit HAPTEX 4.0 Standard (click here to know more about HAPTEX 4.O standard1), but others may have 30% recyclability. Those doesn’t meet the standard of 100% recyclability trade eco benefits for cost and process stability. In this article, I’ll walk you through the three key types of recycled vegan leather we offer at Horizon Leather—fruit leather, RPVB leather and solvent-free vegan leather—so you can choose what suits your product best.

What Makes Fruit Leather Special?

Vegan leather from fruits sounds futuristic—but it’s already here.

Fruit leather is made from plant-based pulp like apple skin, corn stalks, cactus, or even coffee waste, applied to recycled fabric using recyclable coatings.

How Fruit Leather Works

Fruit leather2 relies on plant waste turned into slurry, then applied to fabric backing. The base fabric typically comes from third-party recycling programs and needs strong tensile performance to ensure durability. BASF’s 100% recyclable coating makes it possible to turn the whole composite into a fully recyclable material.

| Feature | Fruit Leather |

|---|---|

| Recyclable Content | Up to 100% |

| Source Materials | Apple peel, cactus, corn stalk, coffee grounds |

| Backing Fabric | Recycled textile |

| Coating | BASF recyclable polymer |

| Pros | 100% recyclable; plant-based; no VOC3 |

| Cons | Costly; inconsistent handfeel; variable supply stability4 |

Among fruit-based sources, coffee grounds5 offer the most stable properties, with better adhesion and batch consistency. However, because every plant pulp and fabric batch is different, the surface feel, glossiness, or elasticity may vary from lot to lot.

When aiming for 100% recyclability6, fruit leather is the most eco-sound choice. But its cost is much higher than 50% recyclable alternatives, and manufacturing involves careful formulation with strict QC.

What Is RPVB Leather Made From?

You’ve heard of recycled fabric, but what about recycled fiberglass?

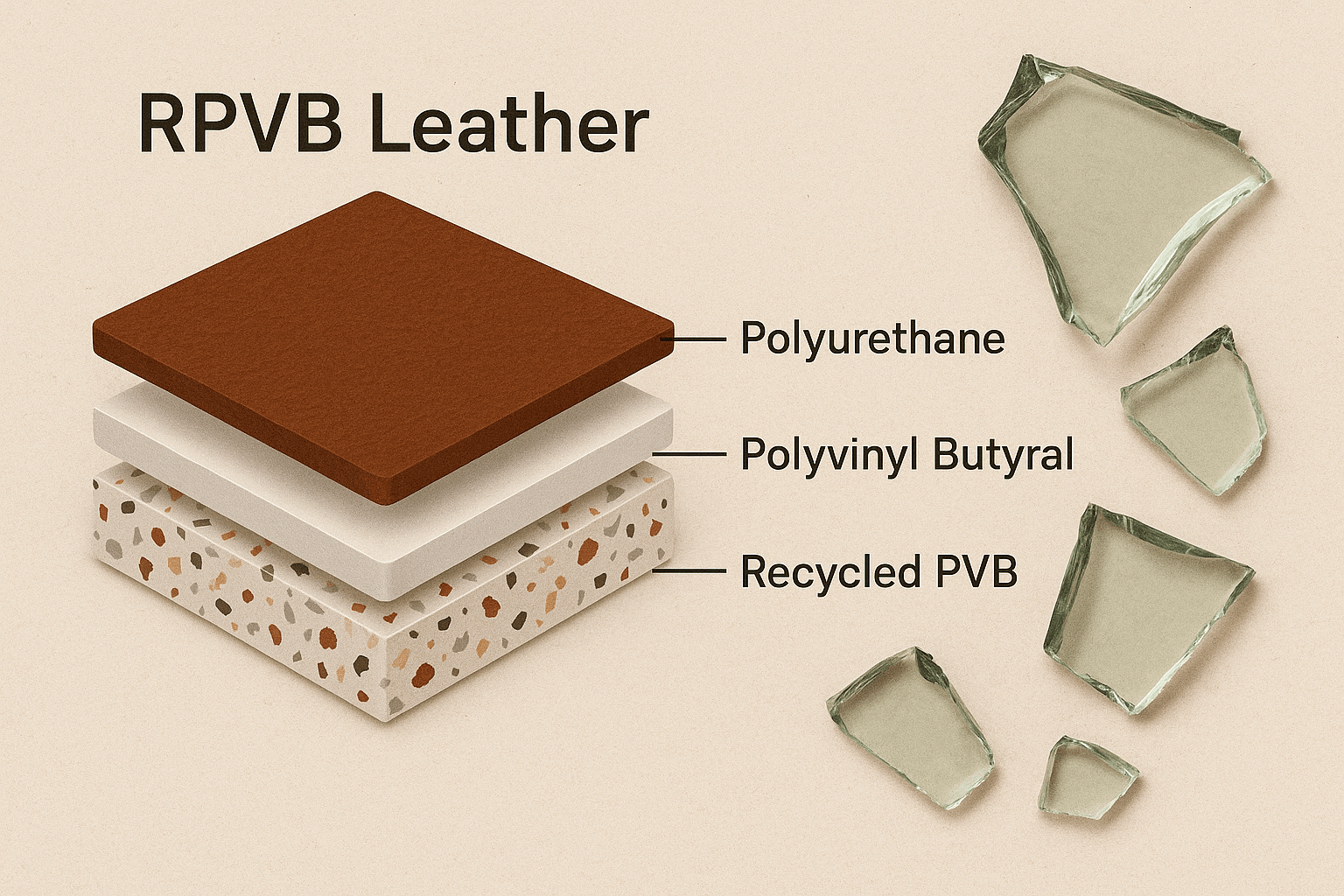

RPVB leather7 is made from glass-fiber fabric8 produced by crushing waste glass and reweaving it, then coated with recyclable polyurethane9 from BASF.

RPVB: The Hidden Champion of Recyclability

RPVB stands for Recycled Polyurethane + Virgin Base, but in modern usage, it now refers to the glass fiber textile used as base. This material achieves excellent consistency in texture, thickness, and mechanical strength, even under harsh temperature or humidity.

| Feature | RPVB Leather |

|---|---|

| Recyclable Content | 50–100% |

| Source Materials | Waste glass -> fiber textile |

| Backing Fabric | Glass fiber woven base |

| Coating | BASF recyclable PU |

| Pros | Highly stable; durable; close to 100% recyclable |

| Cons | Slightly costly; not widely known |

Compared to fruit leather, RPVB leather maintains consistent quality between batches. The material structure is stronger and easier to process, giving it higher reliability across mass production cycles. The cost of RPVB leather is slightly lower than 100% fruit leather, but higher than mid-level solvent-free materials.

For clients looking for a near-zero waste loop and high reproducibility, RPVB leather is a solid fit.

Why Is Solvent-Free Vegan Leather Popular?

Not all PU alternatives are expensive. Solvent-free PU leads the race in practicality.

Solvent-free vegan leather10 is made without harmful solvents, and at 50% recyclable ratio, it’s the most affordable and stable option among the three.

What Makes It So Efficient?

Solvent-free leather uses water-based or dry-coating systems instead of solvents like DMF. That’s not only safer for workers, but also cuts VOC3s and speeds up production.

| Feature | Solvent-Free Vegan Leather |

|---|---|

| Recyclable Content | ~50% |

| Source Materials | Synthetic + partial recycled backing |

| Backing Fabric | Polyester, microfiber blend |

| Coating | Solvent-free polyurethane |

| Pros | Cost-efficient; stable quality; large volume ready |

| Cons | Max recyclability ~50%; not plant-based |

Among our three recycled vegan leathers1, solvent-free PU is the most widely adopted. It’s easier to scale, has minimal production downtime, and rarely causes issues in adhesion or surface quality. Many clients from furniture, auto interiors, or fashion basics prefer this material because it mimics PU leather very closely without the solvent risk.

Which One Should You Choose?

Each recycled vegan leather has its strengths. But which is right for your needs?

| Comparison | Fruit Leather | RPVB Leather | Solvent-Free Vegan Leather |

|---|---|---|---|

| Max Recyclability | 100% | 50–100% | ~50% |

| Cost Level | $$$ | $$ | $ |

| Surface Consistency | Variable | Stable | Very Stable |

| Eco Credibility | Very High | High | Medium |

| Supply Stability | Medium | High | Very High |

| Production Complexity | High | Medium | Low |

At Horizon Leather, we recommend starting with 50% solvent-free vegan leather if you’re new to sustainable material sourcing. If your project requires full circularity11 or marketing value from high eco scores, RPVB or fruit leather is a better match.

Conclusion

Recycled vegan leather isn’t one-size-fits-all. Choose based on your recyclability goal, cost tolerance, and product category.

-

Learn about the main types of recycled vegan leathers to make informed, sustainable material choices for your products. ↩ ↩ ↩

-

Discover how fruit leather is produced and why it’s considered a leading eco-friendly vegan leather option. ↩

-

See how reducing VOCs in production leads to healthier, more sustainable vegan leather products. ↩ ↩

-

Understand the importance of consistent supply in ensuring reliable, large-scale vegan leather production. ↩

-

Discover the innovative use of coffee waste in creating stable, eco-friendly vegan leather materials. ↩

-

Explore the importance of full recyclability in vegan leathers for achieving true circularity and sustainability. ↩

-

Understand the composition and benefits of RPVB leather for high-performance, sustainable applications. ↩

-

Find out how recycled glass is turned into strong, consistent fabric for advanced vegan leathers. ↩

-

Understand how recyclable polyurethane coatings contribute to the durability and recyclability of vegan leathers. ↩

-

Find out why solvent-free vegan leather is widely adopted and how it balances cost, stability, and eco-friendliness. ↩

-

Learn how circularity in vegan leather supports zero-waste goals and sustainable product lifecycles. ↩