As a post processing engineer, I understand how essential surface finishing is in determining the final look, functionality, and market value of a material. Post processing techniques enhance texture, pattern, performance, and usability. At our facility, we offer six professional post processing services, each tailored to meet your specific design and application needs.

1. Cutting Process

Cutting is the foundation of all post processing services. It is more than just separating material into shapes — it defines how efficiently and precisely the material can be used in production.

Techniques We Use:

- Die Cutting: A sharp steel blade is molded into a specific shape, then pressed into the material using a die press. It’s ideal for large-volume production with consistent shapes.

- Digital Cutting: Computer-controlled machines (CNC) ensure high precision and are suitable for intricate designs or prototypes.

- Hot Knife Cutting: This technique uses heated blades to cut synthetic fabrics and seal the edges simultaneously to prevent fraying.

Applications:

- Shoe panels

- Handbag patterns

- Upholstery sections

- Tech accessory components (e.g., laptop sleeves)

Why It Matters:

A well-executed cutting process ensures minimal waste and perfect alignment in assembly. Tolerances are tightly controlled, especially for applications requiring exact fits. Improper cutting leads to poor product quality, stitching issues, and material deformation.

2. Printing Process

Printing adds design, branding, and performance elements to the material. It transforms plain fabric into eye-catching, high-value surfaces.

Common Printing Methods:

- Digital Inkjet Printing: Offers photographic-quality results. Suitable for custom, short-run jobs.

- Foil Transfer Printing: A metallic or colored foil is heat-pressed onto the material for reflective or premium effects.

Applications:

- Logos and brand marks

- Custom patterns

- Fashion graphics

- Instructional markings

Why It Matters:

Precision in the printing process ensures long-lasting colorfastness and clarity. UV resistance, abrasion resistance, and water-proof coatings can be integrated during printing to enhance performance.

3. Embossing Process

Embossing gives material a three-dimensional appearance. It adds tactile and visual depth to otherwise flat surfaces.

Techniques We Use:

- Cold Embossing: Pressure is applied using a metal plate to press patterns into the material without heat.

- Hot Embossing: Combines heat and pressure to permanently imprint designs — great for PU and PVC leather.

- Roller Embossing: Uses patterned rollers for continuous embossing in large quantities.

Applications:

- Decorative textures (crocodile, lizard, pebble grain)

- Logos or brand names

- Anti-slip patterns for functional products

Why It Matters:

Embossing alters surface geometry, improving grip, aesthetic appeal, and sometimes even mechanical properties. Proper alignment and even depth are critical for consistency, especially in high-end fashion and automotive applications.

4. Quilting Process

Quilting adds volume and softness by stitching or bonding fabric with a padding layer inside. It is often used where cushion, insulation, or visual depth is required.

Quilting Types:

- Ultrasonic Quilting: No needle or thread — bonding is achieved through high-frequency vibration.

- Thread Quilting: Traditional needle stitching forming patterns like diamonds, waves, or custom logos.

- Heat Press Quilting: Foam or fiberfill is pressed into fabric with heated molds to form permanent quilted impressions.

Applications:

- Fashion outerwear

- Automotive interiors

- Soft travel bags

- Protective sleeves

Why It Matters:

Quilting improves structure and comfort. Stitch uniformity, filler density, and thermal stability are key factors. A poorly quilted material may flatten, shift, or pucker over time.

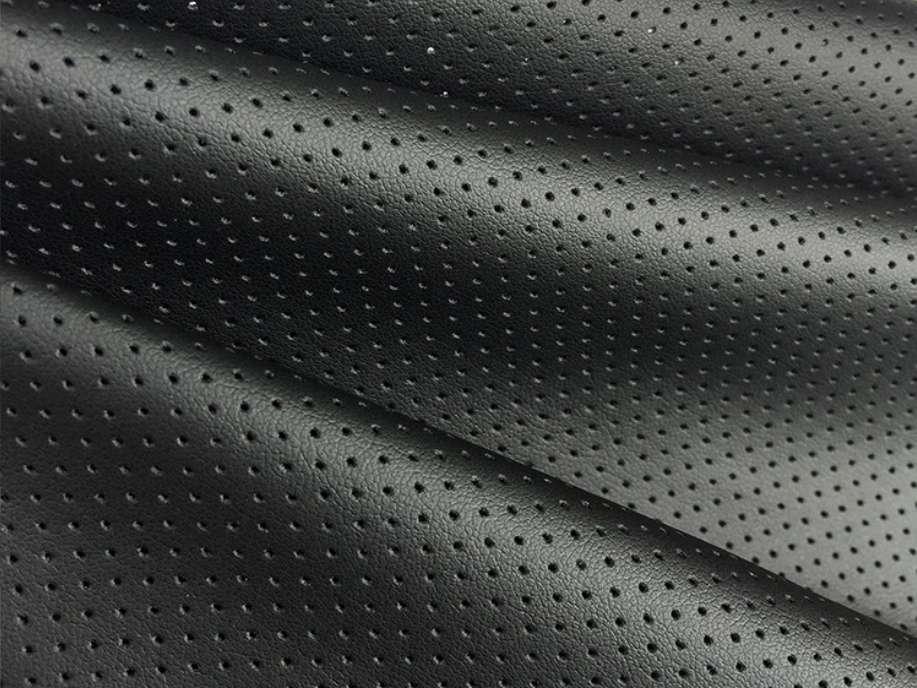

5. Punching Process

Punching, or perforation, involves creating holes or patterns on the material’s surface. It enhances both aesthetics and functionality.

Types of Punching:

- Mechanical Punching: Die or needle arrays punch holes into the fabric in consistent patterns.

- Laser Punching: High-precision laser beams cut patterns into the surface without fraying or scorching edges.

- Pinhole Punching: Micro-perforation used to enhance breathability without affecting appearance.

Applications:

- Ventilation in footwear

- Breathable linings

- Decorative effects in fashion and automotive interiors

Why It Matters:

Punching must be precise to avoid compromising the material’s strength. Hole size, spacing, and shape directly impact comfort, airflow, and design consistency.

6. Shrinking Process

Shrinking is a controlled post-processing method that compacts or distorts the surface of the material to achieve a unique texture or tensioned surface.

Shrinking Techniques:

- Heat Shrinking: Material is exposed to high heat which activates internal stress, causing the surface to tighten or wrinkle.

- Steam Shrinking: Uses pressurized steam to gradually shrink and reshape material, typically for natural fibers.

Applications:

- Wrinkled effects for fashion

- Pre-shrunk textiles for precise sizing

- Enhancing elasticity or material rebound

- Creating grain-like textures in vegan leather

Why It Matters:

Proper shrinking increases form stability and adds a designer surface texture. It must be carefully monitored to avoid warping, tearing, or undesired distortion.

Final Thoughts

These six post processing services are vital to transforming raw materials into functional, beautiful, and commercially viable products. Whether you’re designing a luxury handbag, a sporty car seat, or a breathable pair of shoes, our facility offers the technical capability and process control you need to achieve your desired results.

If you’re unsure which combination of processes suits your product best, contact our technical team for customized recommendations and prototypes.